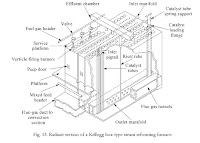

Naphtha reformer for Hydrogen production

To reform natural gas or naphtha which are rich sources of hydrocarbon are reformed to produce Hydrogen using reforming equipment that consists of side-fired radiant burners that externally heat feedstock. There will be about six rows of burners across four sides and 15 burners in each row. Feed passes through the catalyst bed, and CH4 (Methane) or Naphtha vapors which are converted to methane react with steam to give Hydrogen and carbon dioxide.

Natural Gas Plant Design and Process Description

Natural Gas is a combustible gas that is available in the earth’s crust, mainly under the rocks where there is a petroleum deposit. Natural Gas will be along with crude petroleum and in some cases, it exists individually. Natural Gas is used as an energy source next to liquid petroleum and solid coal, it is an important raw material for the production of petrochemicals. The general composition of Natural Gas contains 70 to 98% of Methane, 16% of alkanes from Ethane to Hexane, and 15% of Nitrogen, Carbon dioxide, and Hydrogen Sulphide.

Natural Gas Processing has direct and indirect paths to get various derived chemicals and energy.

- Direct method Natural Gas is combusted or partially combusted without the catalyst to form Formaldehyde, C2H4, C2H6, CO, and H2.

- By the Indirect method, Natural Gas is processed to produce a SYNTHESIS GAS. where all the hydrocarbons are converted to Hydrogen and Carbon-monoxide mixture, this becomes a starting material for the production of various petrochemicals like Ammonia, Methanol, Acetic acid, Phosgene, Oxo alcohols, metal carbonyls, hydrocarbons. Steam reforming is the technique used for the production of synthesis gas from natural gas.

Steam reforming of Natural Gas:

Natural gas and Steam are reacted on a catalyst at operating conditions leading to the production of synthesis gas, the reaction on the catalyst(Ni6 Al2(OH)16. CO3.4H2O) would be like

CH4 + H2O <=> CO + H2

Related Essay

- SULPHATES Determination Test | Sulphites Determination | Determination Of Sulphate And Sulphide In Water

- Petrochemical Products From Propylene | Types Of Pressure Gauges | Types Of Reactors Used For Chemical Reactions And Chemical Process

- Printing Machine And Devices | Propellers Of A Ship

- Predesulphurization Of Raw Naphtha Process Plant Flow Sheet

- Phosphoric Acid Per Day Flow Sheet Of Dihydrate Process

- Types Of Phenol Manufacturing Process

- Chlorobenzene And Caustic Process For Phenol Production | Phenol Production By Benzene Sulfonation Process

- Bin Blender Applications

- Operating Procedure For Liquid-Liquid Extraction In Packed Column