Liquid-liquid extraction, familiarly called solvent extraction is a unit operation that involves the liquid-liquid contact method. It is based on the principle of separation of individual components of a solution mixture by using another insoluble liquid. The extraction phenomena work on the solubility property of the liquid mixture and on the pure solvent used in the separation or purification process. The operation of the liquid-liquid extractor entirely differs from the operation procedure of the distillation column. For a packed extraction column operating procedure can be understood at the startup of the column for a plant operator or an engineer.

A standard procedure designed for most packed extraction columns:

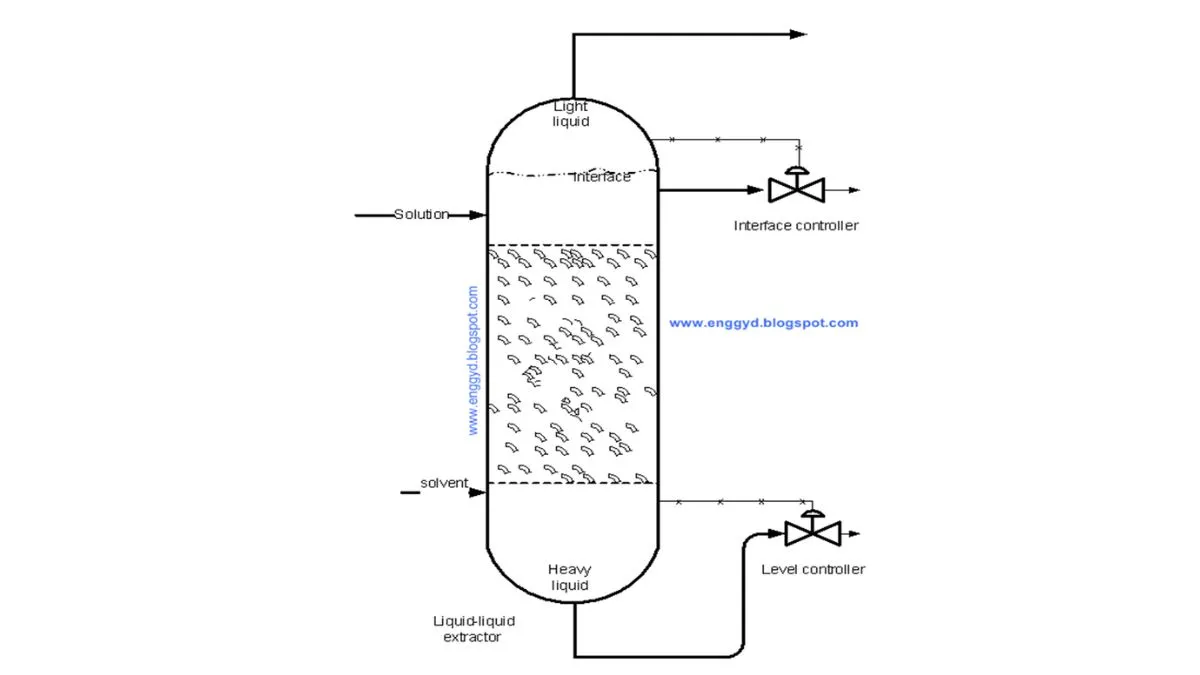

- The heavy liquid (solution) which has more density is fed from the top side of the column and the light liquid (pure or recycled solvent) from the bottom.

- At initial condition, the light liquid is passed into the column through the distributors and the steady flow rate is maintained.

- Then the heavy liquid is passed with the flow rates approximately to the ratio based on the density of the heavy liquid and light liquid, that of light liquid flow rates.

- The above step leads to attaining the concentration gradient of the solute which diffuses into the light liquid.

- And so heavy liquid pass down the column having contact with the fresh light liquid.

- The sample analysis is made to confirm the concentration at bottom of the column when the bottom outlet control valve is opened.

- The pressure at bottom of the column is maintained in such a way as to determine the position of the interface in the column.

For an extraction column, two control valves play an important role in controlling the complex process.

- Heavy liquid outlet Bottom control valve.

- The interface level control valve.

Mass transfer occurs at the interface of the two phases so, the interface position is important in achieving the maximum distribution of solute. The interface control valve placed above the heavy liquid distributor maintains the level and is used to remove the particles or foam material formed during the operation.

A detailed diagram can help to understand the operation of the solvent extractor.

Related Topic click here

- SULPHATES Determination Test | Sulphites Determination | Determination Of Sulphate And Sulphide In Water

- Petrochemical Products From Propylene | Types Of Pressure Gauges | Types Of Reactors Used For Chemical Reactions And Chemical Process

- Printing Machine And Devices | Propellers Of A Ship

- Predesulphurization Of Raw Naphtha Process Plant Flow Sheet

- Phosphoric Acid Per Day Flow Sheet Of Dihydrate Process

- Types Of Phenol Manufacturing Process

- Chlorobenzene And Caustic Process For Phenol Production | Phenol Production By Benzene Sulfonation Process

- Bin Blender Applications