What Is Meant By Compounding Of Turbine? types, Advantages Of Compounding

Compounding of a turbine refers to the process of using multiple stages of turbine blades to extract energy from the steam or fluid passing through the turbine. Each stage of blades is designed to extract a specific amount of energy from the fluid, and by using multiple stages, more energy can be extracted overall.

Three Methods Of Compounding In Steam Turbines

- Pressure compounding

- Velocity compounding.

- Pressure-velocity compounding.

- Pressure Compounding (RATEAU).

- The expansion of steam from boiler pressure to exhaust pressure is carried out in a number of steps or stages. Each stage has a set of nozzles and a row of moving blades. The rows of moving blades are separated from each other by partitions or diaphragms, into which the nozzles are set.

- As only a portion of the velocity available is developed in each set of nozzles, the blade velocity is kept down to a reasonable amount. This type of compounding is known as pressure compounding and the nozzle and blade arrangement for a pressure-compounded impulse turbine is sketched.

- In this arrangement, the pressure of the steam drops in each set of nozzles as indicated by the pressure graph. The steam velocity is increased by each pressure drop and then decreases again in each row of moving blades, as the velocity graph shows.

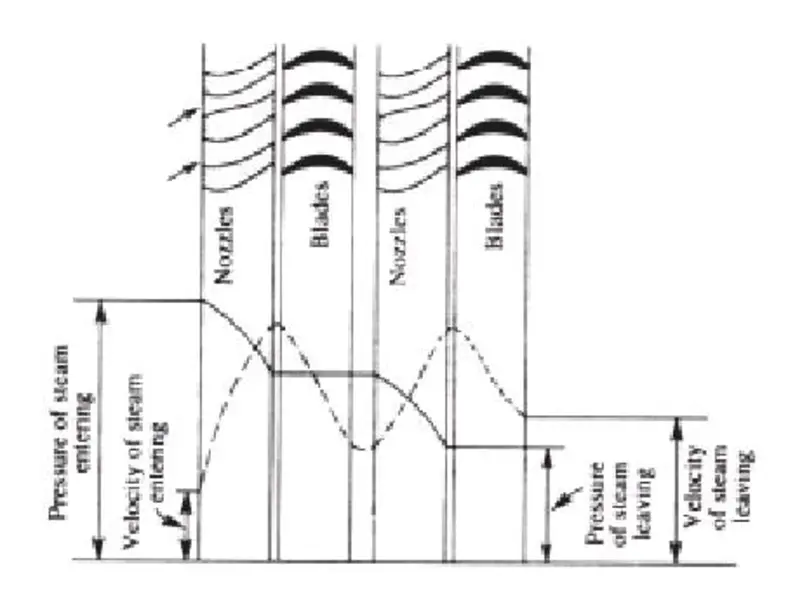

Fig: pressure compounding

- This amounts to a number of simple impulse turbines in series, the nozzle of one stage receiving steam discharged by the preceding ring of moving blades. The distribution of the total enthalpy drop to a number of sets of nozzles will be about the same and the velocity of steam at the outlet of each set of nozzles will be lower than the maximum velocity obtainable by single expansion.

- The work output of a pressure-compounded turbine is the sum of that produced by the separate impulse stages. However, the velocity of steam at the entrance to nozzles particularly after the first stage must be taken into account.

2. Velocity Compounding (CURTIS):

- This design consists of one set of nozzles in which the steam is expanded from initial to exhaust pressure. The velocity of the steam resulting from this expansion is absorbed in two or more rows of moving blades.

- Rows of fixed or guide blades, attached to the casing, are set between rows of moving blades and receive and redirect the steam to the next row of moving blades. As the velocity is absorbed in more than one row of moving blades, the blade speed is less than if the velocity was all absorbed in one row of blades.

- This type of compounding is known as velocity compounding and the blade and nozzle arrangement for a velocity-compounded impulse turbine is shown.

- The pressure drops from inlet pressure to exhaust pressure in the single set of nozzles as the pressure graph shows. This large single-pressure drop produces high steam velocity, which is absorbed in the two rows of moving blades. Note that there is no pressure or velocity drop in the fixed guide blades.

3. Pressure-Velocity Compounding

- This is a combination of the first two methods of compounding, namely pressure compounding and velocity compounding. The steam is expanded in two or more sets of nozzles in series, each set having velocity compounded blades to receive the steam issuing from the nozzles.

- The arrangement shown in Figure features two sets of nozzles. The steam pressure drops in each set of nozzles and the resulting velocity increase in each case is absorbed by two rows of moving blades having a row of stationary blades in between them.

- The methods of reducing rotor speeds, namely, pressure compounding, velocity compounding, and pressure-velocity compounding have all been applied to impulse turbines.

- In the case of the reaction turbine, it is not necessary to make special blade arrangements to reduce rotor speed. This is because the pressure drops across each row of moving blades as well as across each row of fixed blades and consequently the pressure drops in every stage and in small amounts all through the machine.

- This requires, however, a large number of alternate rows of fixed and moving blades resulting in a long machine.

- Therefore, in order to reduce the number of blade rows necessary, reaction turbines frequently have a velocity compounded impulse stage at the inlet end of the machine.

Advantages of compounding in turbines include:

- Increased efficiency: By using multiple stages, more energy can be extracted from the fluid, leading to increased efficiency.

- Reduced size and cost: Using multiple stages allows for a smaller turbine to be used, reducing the size and cost of the turbine.

- Improved reliability: Compounding allows for the turbine to be designed with smaller, simpler, and fewer components, which can lead to increased reliability.

- High specific speed: Compounding allows for a turbine to operate at high specific speeds, which is useful in certain applications.

- High head and low flow: Compounding allows for a turbine to operate at high head and low flow conditions which is useful in certain applications.

It should be noted that compounding increases the complexity of the turbine which in turn increases the cost of maintenance and repair.